What is Supply Chain Management and Why is it so Important

What is Supply Chain Management and Why is it so Important

Cross-border logistics typically face more challenges in comparison to local logistics. Factors that affect the efficiency of a cross border fulfillment company includes shipping duration, transportation costs, inventory as well as supply and demand. This is where supply chain management intervenes to play a prominent role.

What is Supply Chain Management (SCM)?

In cross-border logistics, supply chain management acts as the manager of volume flow of products and services along with management of processes that creates a more systematic logistics company in terms of supplying activity. This is to ensure a maximized value for the logistics provider, its clients and to gain a significant advantage in the industry.

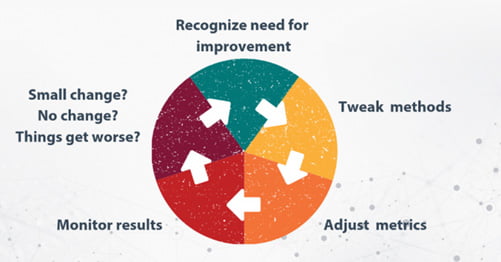

In order to guarantee the improvements through supply chain management in logistics companies, certain steps should be followed. Some of these methods include:

- Focus on lead time and planning for order/delivery operations.

- Conduct evaluations on current standard operating procedures (SOP) and adjust where needed.

- Evaluate modes of shipping and re-design them to minimize cost and maximize productivity.

- Ensure warehouse management and that the operations are running to produce optimal productivity.

- Utilize and optimize automation as well as consider industrial technology (Bic Magazine, 2018).

The Basic Components of SCM

Supply chain management can be categorized into 5 components. Below are the detailed yet brief explanations of each component.

1. Plan– Organizations make tactical strategies to fulfil consumer demand for goods and avoid a bullwhip impact (effect due to order variances that may be higher than sales, demand distortion flows upstream in the supply chain from the retailer to the wholesaler and manufacturer) using supply chain analytics and materials management tools in ERP systems.

2.Source– Organizations seek and select vendors that can provide materials in a timely and efficient manner in accordance with agreements. Collaboration in the supply chain begins at this point and is crucial throughout the supply chain management process.

3. Make– Products are manufactured at this stage. It includes planning the manufacturing, testing, ensuring that compliance standards are met, packing, storage, and distribution. The involvement of multiple machines is likely, especially in larger businesses, which are increasingly utilizing technologies to improve efficiency.

4. Deliver– The delivery stage is concerned with logistics and focuses on getting finished items to customers via whatever means are necessary. At this point, inventory management and warehouse management solutions are extremely important. Also, more emphasis is being placed on doorstep delivery as the Amazon effect has developed (Mitchell, 2021), particularly as a result of COVID-19. Supply chain leaders are now expected to collaborate more closely with customer service.

5. Return– In the return stage, all product returns including faulty items and products which will no longer be supported. Other stages’ features, such as inventory and transportation management are also included in this stage.

Forecast by Experts On SCM

Adaptability is also a highly significant factor that plays a big role in supply chain management. In light of the recent pandemic, the Coronavirus (COVID19), countless businesses have not been successful in adapting and overcoming the devastating circumstances. However, Savills Malaysia, a local and international property company, predicts the logistics and industrial sector to be part of the top performers in the year 2021. Savills Head of Agency, Kevin Goh also mentioned that warehousing would be held afloat by the storage and logistics demand, and as eCommerce businesses continue to progress, further growth is predicted. (The Edge Markets, 2021).

Furthermore, a study in 2018 titled “Supply Chain Management Practices in Malaysia Consumer Goods Industry” showed a significant impact of information sharing on supply chain responsiveness, followed by customer relationship and strategic supplier partnership respectively. It is found that sharing information was positively, directly proportional to customer relationships, supplier partnership and supply chain responsiveness. Therefore, cross border logistics companies in Malaysia should strive to amplify their ability to share information. This may range from hiring multilingual communications teams to building relationships with overseas logistics companies to build connections and move towards serving the Asian market, if not on a global scale.

References:-

- https://www.bicmagazine.com/departments/maintenance-reliability/5-ways-to-improve-the-logistics-management-process/

- https://www.theedgemarkets.com/article/industrial-and-logistic-sectors-be-top-performers-2021-%E2%80%94-savills-malaysia

- https://www.researchgate.net/publication/327791072_Supply_Chain_Management_Practices_in_Malaysia_Consumer_Goods_Industry

- https://www.investopedia.com/terms/a/amazon-effect.asp